Built Up section Weld size. Local buckling including the effect of stitch welds on the local buckling of plates.

A Rooban Tharsy Built Up Column I Section Design Tensile Test For Fillet Weld

621 Limitations on weld dimensions See AISC Spec.

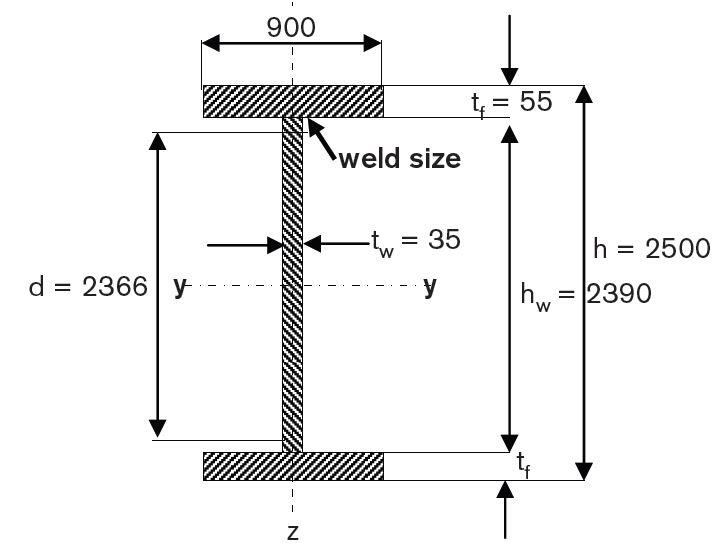

. The design of a built-up beam involves the selection of adequate individual section sizes weld sizes and stiffeners if required and verifying their performance as a composite whole in satisfying ultimate and serviceability limit state requirements. Any number of plates or sections may be used. The size of fillet weld is 6 mm.

KootK Structural 7 Aug 20 1558. Compute the maximum shear force that may be allowed at any section if the average allowable shear in the web is 04 f y and maximum allowable shear in the weld is 110 Nmm 2. In weld design problems it is advantageous to work with strength per unit length of the weld or base metal.

However if the load actually applied is more than the above specified value the connection shall be designed for actually applied load. 6mm fillet weld on both sides of the web 90 mm hit and 110 mm miss. How intermittent welds affect the section properties of a built-up member.

Can we use the fillet weld to make the box section. The assumption is that you are talking about connecting elements like flanges and webs using plates to create a girder beam. Part ACommon Requirements of Nontubular and Tubular Connections.

If the member is subjected to flexure the. An example problem will be used to. J22b on page 161-54 of manual Minimum size amin.

Built-up sections can be bolted or welded. This calculation is useful to find out the Filet weld required by AISC - LRFD. By extending one side of the plate to accomade fillet weld.

The 6mm fillet weld leg length required over 200 mm 200. Y ΣyA ΣA Itotal I1 I2 A1Y-y1 2 A 2Y-y2 2 Scompression I Y Stension I d-Y rx Itotal ΣA 12. In a built-up I-shaped cross-section how are welds connecting the plates designed.

This part covers the requirements applicable to all connections regardless of the product form or the type of loading and shall be used with the. Built-up members are specified by the designer when the desired properties or configuration cannot be obtained in a single hotrolled section. Otherwise youll have to design for the change in Centre of mass.

Always check weld metal and base metal strength. This section covers the requirements for the design of welded connections. However current construction methods and design guidelines almost exclusively encompass the use of single-section members Fig.

It is divided into four Parts de-scribed as follows. Apply the standard formula. It can get more complicated if youre looking at significant torsion or axial loads however.

The usual technique is is to size the welds for longitudinal shear flow with VQIt for basic flexure etc. Assuming that continuous fillet welds are used the welds may be minimum size per the AISC Specification Table J24 fillet welds if the member is subjected only to axial compression or tension. Both are necessary for the design of beam reinforcement.

Welded members in general are less expensive because much less handling is required in the shop and because of more efficient utilization of material. Built-up Sections and Shear Flow The following section is a review of the procedures for analyzing built-up sections and calculating shear flow. The column is mainly subjected to compression load.

Fillet weld PJP or CJP would work. The built-up beams are used when the span load and corresponding bending moment are of such magnitudes that rolled steel beam section becomes inadequate to provide required section modulus. In most cases the weld metal strength will govern.

Sometimes in specification it is mentioned that for built-up plated TI-section weld size shall be designed for 80 of full shear capacity and some specification keeps it as 60. Usually Structural steel contractors required to propose alternate built up beam proposal in place of rolled section due to various reasons mainly non availability of profile. A built-up beam is also known as compound beam.

Find this Pin and more on Structural systems by Erin Tompkins. Double sided - in order to maintain symmetry. Theory of Built-up Sections.

For one of the High rise Steel building I am using the Built-up Box Section as a column. The average shear resistance per mm is 9012200 101 039 037 kN mm OK. Weld design including the calculation of weld strength for built-up columns.

Answer 1 of 4. For two welds this is 032 kNmm per weld. ABuilt-up I-beam b Hot rolled I-section.

23 Section Properties of Built-Up Steel Sections Description This document calculates the moment of inertia and section modulus for a steel section that has at least one axis of symmetry built-up from plates or from a combination of plates and sections with known section properties. S 400 9000 285 16 109 064 kNmm. 1a whereas there is a growing interest in industry to extend the applications of cold-formed steel to larger structures by connecting several single sections to form built-up cross-sections with higher axial and bending capacities as.

The web plate of a built-up welded I-section is 200 mm x 12 mm and the flange plates are 100 mm x 12 mm. Provided on the design of built-up columns. February 20 2010 by Designer.

The weld will be designed only of the the transverse shear.

The Mechanics Of Built Up Cold Formed Steel Members Sciencedirect

Single Fillet Weld In Build Up Hollow Section Subjected To Lateral Bending Structural Engineering General Discussion Eng Tips

Lec19 Shear Flow In Built Up Members Part4 Example2 Youtube

Built Up Shape Weld Or Bolt Structural Engineering General Discussion Eng Tips

How To Design Built Up Beams Welded Plate Girders Structville

Built Up Section Welded Plate Girder Steel Beams Beams Structural Engineering

Stub Column Tests On Stainless Steel Built Up Sections Sciencedirect

How To Design Built Up Beams Welded Plate Girders Structville

0 comments

Post a Comment